New EV-Battery Technology allows Electric Cars to be recharged in six minutes.

Header picture : Newable

Six minutes lithium battery recharge for phones and electric cars on his way

Echion Technologies, the Sawston-based battery specialist spun out of Cambridge University, is preparing to commercialise technology which has been trialled to allow charging times for both mobiles and electric cars to drop to six minutes.

The development could revolutionise the electric transport era, allowing electric car owners to recharge at any garage over a cup of coffee rather than having to stay close enough to recharge overnight at home.

The restrictions are being lifted thanks to technology which involves replacing graphite with a new material, possibly a compound – but Dr Jean De La Verpilliere isn’t saying what.

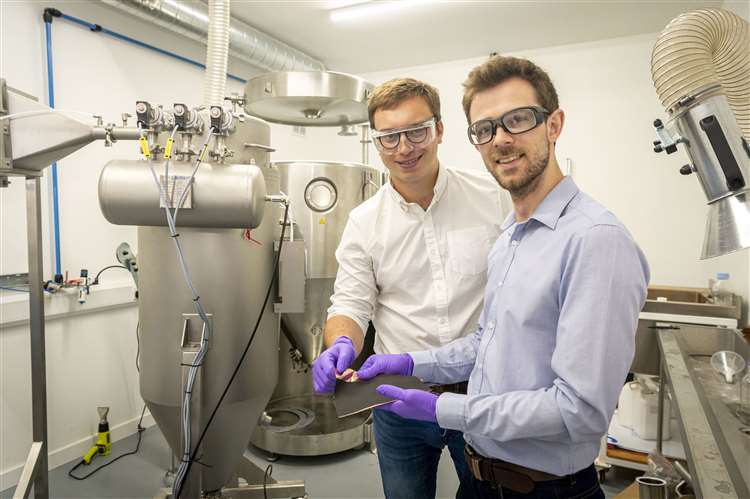

Echion is the brainchild of Dr De La Verpilliere. Two years ago, while studying for a PhD in nanoscience at the University of Cambridge, he created a material that could be used in lithium batteries. In 2017 – the final year of his phD – he founded Echion, with a focus and expertise on high performance materials innovations for lithium, or Li-ion, batteries. Echion “engages with chemicals and battery cell manufacturers to integrate its materials solutions into next-generation products”. Currently, materials are simply ‘dropped in’ to lithium battery infrastructure.

One of the materials is graphite, which Echion has replaced with its own material.

“The powders are the central component of a lithium battery,” Jean says. “This is a new kind of powder which allows you to recharge in six minutes, not 45 minutes. This includes a car, so your electric caris almost as easy to charge as it is to refuel conventionally.”

There’s another benefit: the new material doesn’t explode.

“The problem with the usual powders is that when you fast-charge them they can cause an explosion. With the new material – which I can’t tell you any more about – it will accept fast-charging with no safety hazard, unlike graphite.”

Aided by two academic supervisors, Echion secured funding from Cambridge Enterprise. Today, the company can produce 1kg of powders a day, enough for a single car battery- but that’s about to change.

“We’re working on methods to make powders which are scaleable and where 1,000 tonnes could be made quite easily in factories,” says Jean. “We have a prototype now, and are moving towards commercialisation early next year. The tests have to be validated beforehand.”

A second investor, Newable Private Investing, has joined Cambridge Enterprise. Newable’s investment director Alex Sleigh said: “As an investment team, we felt the product that Echion was producing was superior to anyone else in the market, particularly with regards to the time required to charge the batteries.

“Furthermore, the support that Echion received from a world-class institution in the form of Cambridge Enterprise gave us huge confidence, allied to our view that the majority of autonomous vehicles in the future will be powered by battery technology.”

Echion is now looking to hire two sales representatives for commercialisation in 2020. Echion has held productive conversations with a number of OEM companies while also securing an official partnership with Vantage Power, a company that designs and manufactures electric and hybrid systems for buses and heavy goods vehicles.

By Mike Scialom – mike.scialom@iliffemedia.co.uk

Pictures : Keith Heppell

Source Text & Images : Cambridge Independent